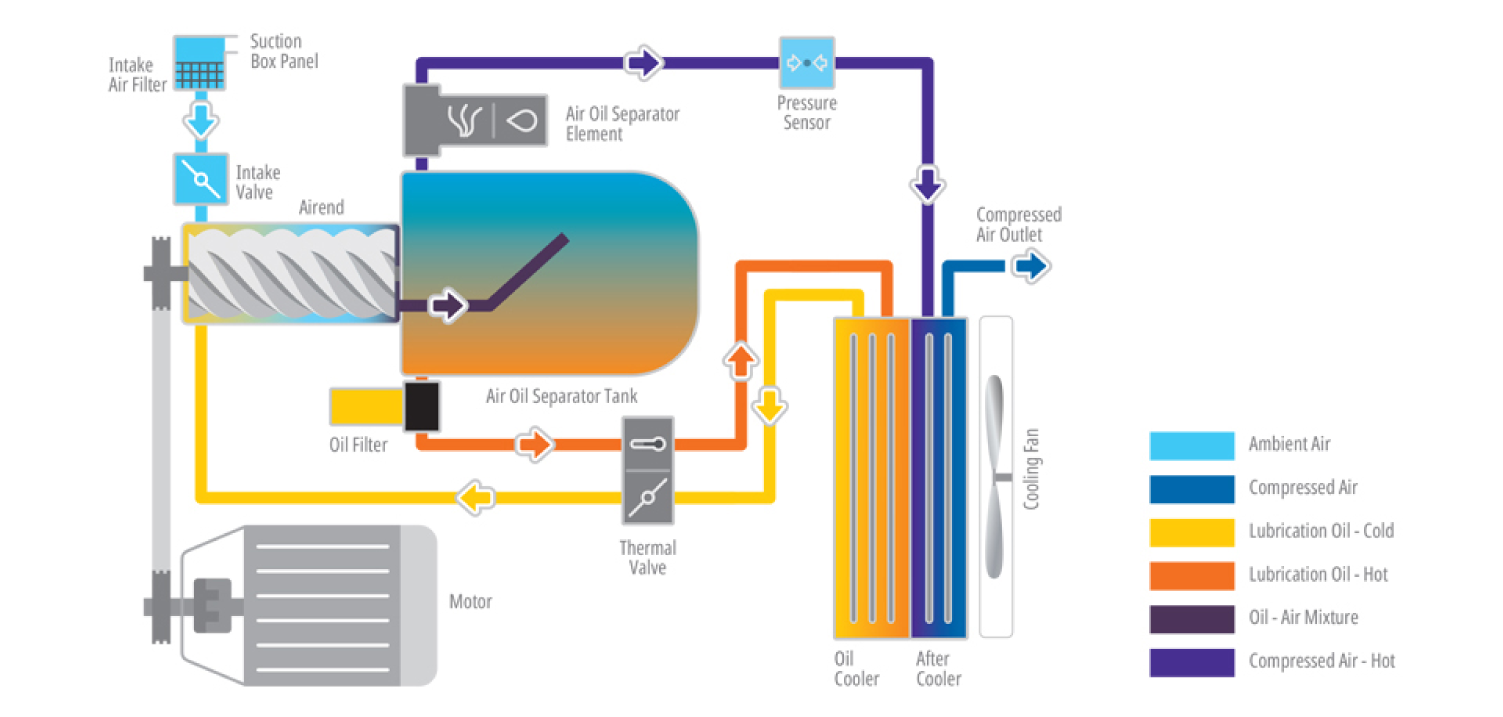

SCHEMATIC REPRESENTATION 2.2-45 KW EN Series Rotary Screw Compressor

Rotary Screw Compressor Malaysia - EN-Series Screw Compressors

The EN-Series delivers a reliable rotary screw compressor Malaysia industries trust for continuous, stable, and energy-efficient air supply. Built for demanding industrial environments, this screw air system offers consistent performance, low noise, and reduced operating costs. Whether for manufacturing, automotive, packaging, or general production lines, the EN-Series rotaary screw compressor ensures clean, dependable airflow. Designed to perform in Malaysia’s climate, it is a durable and efficient industrial air compressor solution suitable for daily heavy-duty use.

Key Features of Rotary Screw Compressors

- High-efficiency screw airend for maximum output

- Energy-saving motor with low heat generation

- Intelligent control system with real-time monitoring

- Robust cooling system optimized for Malaysian temperatures

- Low-noise operation suitable for indoor factory use

- Compact, easy-maintenance design

Applications

- Manufacturing and production plants

- Automotive workshops & assembly lines

- Electronics and semiconductor factories

- Food, packaging, and bottling plants

- General industrial compressed air systems

Why Choose Our Rotary Screw Compressor

AED Kompressoren is a reliable provider of rotary screw compressor solutions in Malaysia, offering reliable products backed by professional consultation and technical expertise. Our team helps you select the right capacity and pressure for your application, ensuring optimal performance and efficiency. We provide complete installation, servicing, and preventive maintenance to keep your compressed air system running at peak condition. With genuine ELGi parts and fast support, we deliver a dependable industrial air compressor solution for Malaysian businesses.

FAQs

Rotary screw compressors offer several advantages, including high efficiency, continuous operation capability, and low noise levels. They are well-suited for applications requiring a constant supply of compressed air, such as manufacturing, automotive, and food processing industries in Malaysia.

Yes, rotary screw compressors are designed to handle varying load demands efficiently, thanks to features such as variable speed drives (VSD) or modulation control. These systems adjust the compressor’s speed or capacity according to the air demand, ensuring energy savings and stable air supply in fluctuating conditions.

Yes, rotary screw compressors are suitable for use in Malaysia’s tropical climate, provided they are properly installed and maintained. Adequate ventilation and cooling systems help dissipate heat generated during compression, ensuring reliable operation even in high ambient temperatures and humidity levels.

Rotary screw compressor oil should typically be changed every 2,000–4,000 operating hours, depending on the model, oil type, and working conditions. Regular oil changes help maintain efficiency and extend compressor lifespan.

Rotary screw compressors can save up to 20–30% more energy than piston compressors. Their efficient design and ability to run continuously make them ideal for industries needing a steady air supply.

A rotary screw compressor provides continuous, low-noise airflow for long-hour use, while a piston compressor delivers intermittent, higher-noise air suitable for lighter or short-duration applications.

Yes. Rotary screw compressors deliver steady, pulse-free air, ideal for machines requiring stable pressure.

Yes. They use fewer moving parts, long-life components, and easy-access service panels to reduce maintenance effort.

Yes. Rotary screw compressors produce low vibration due to their continuous rotary motion and balanced internal design.

Yes. The low-noise and efficient cooling design make it suitable for indoor industrial environments.

WHY ELGi's EN SERIES?

Best-in-class reliability

Compact and elegant design

Energy-efficient, encapsulated airends

Best-in-class maintenance and operating cost

Efficient air-oil separation

Optional variable speed drives for energy efficiency

Indigenously designed Neuron control system offering operating data and safety measures

Highly efficient belt drive transmission

TEXTILES

FOOD PROCESSING

PAPER

AUTOMOTIVE