Oil-free compressors in Malaysia are advanced air compression systems that operate without the need for lubricating oil. These compressors are designed to deliver clean and contaminant-free compressed air, making them ideal for applications where oil-free air is crucial, such as in industries like pharmaceuticals, food and beverage, electronics, and healthcare. The absence of oil in the compression process ensures that the compressed air remains free from impurities, making it suitable for sensitive equipment and processes. Oil-free compressors contribute to environmental sustainability by eliminating the risk of oil contamination and reducing maintenance requirements, making them a reliable and efficient choice for various industries in Malaysia.

Oil lubricated compressors offer several advantages, including higher efficiency, smoother operation, and longer lifespan of compressor components. They are also better suited for heavy-duty industrial applications and can handle continuous operation with minimal maintenance requirements.

Yes, oil lubricated compressors are designed to operate effectively in various environmental conditions, including Malaysia’s tropical climate. Proper ventilation and cooling systems ensure that the compressor can maintain optimal performance even in high temperatures and humidity levels.

Yes, oil lubricated compressors can be used in industries with stringent air quality requirements, if they are equipped with appropriate filtration systems to remove any oil contaminants from the compressed air. It’s crucial to select compressors with high-quality filtration options to meet the specific needs of these industries in Malaysia.

WHY ELGi's AB SERIES?

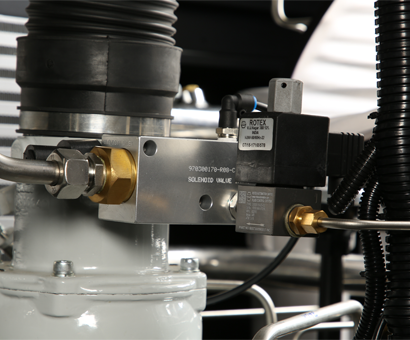

Class-0 certified as per ISO8573-2010

Our Oil Free Series have consistent oil-free air meeting ISO8573-1 class 0 oil standards. Food grade material of air contacts metal surface inside the compressor ensures consistent oil-free air without metal debris. Pipes have special e-coating which ensures consistently clean and oil-free air along with optimized rotor clearances which ensures consistent air delivery

Viable Microbiological content complying to ISO8573-7:2003

These compressors discharge air with no microbiological containment, complying with ISO 8573-7 standard

Pure Water quality complying to IS:10500-2012

To maintain the quality of water ELGi machines have a closed loop water circuit which eliminates the need for a RO system. This reduces power & maintenance cost for our customers and ensures pure water quality complying to IS:10500-2012

Corrosion resistant SS rotors

ELGi machines use FDA approved stainless steel with proprietary coating which eliminates any chances of corrosion

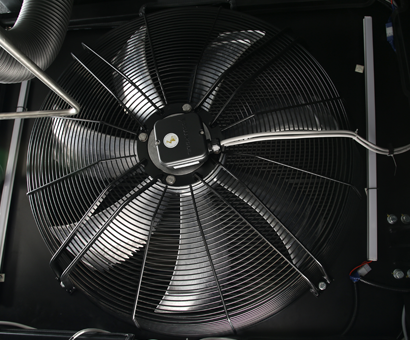

Compact, air cooled package

The cooling system with fans and larger cooling surface area enhances the cooling of hot air. The fan motor uses significantly low power. The integrated fan-motor assembly maintains low temperature thereby increasing life of the motor

Lower maintenance cost

The efficient rotors with best in class performance, single-stage operation, low operation speed and application-oriented design, lowers overall maintenance

TEXTILES

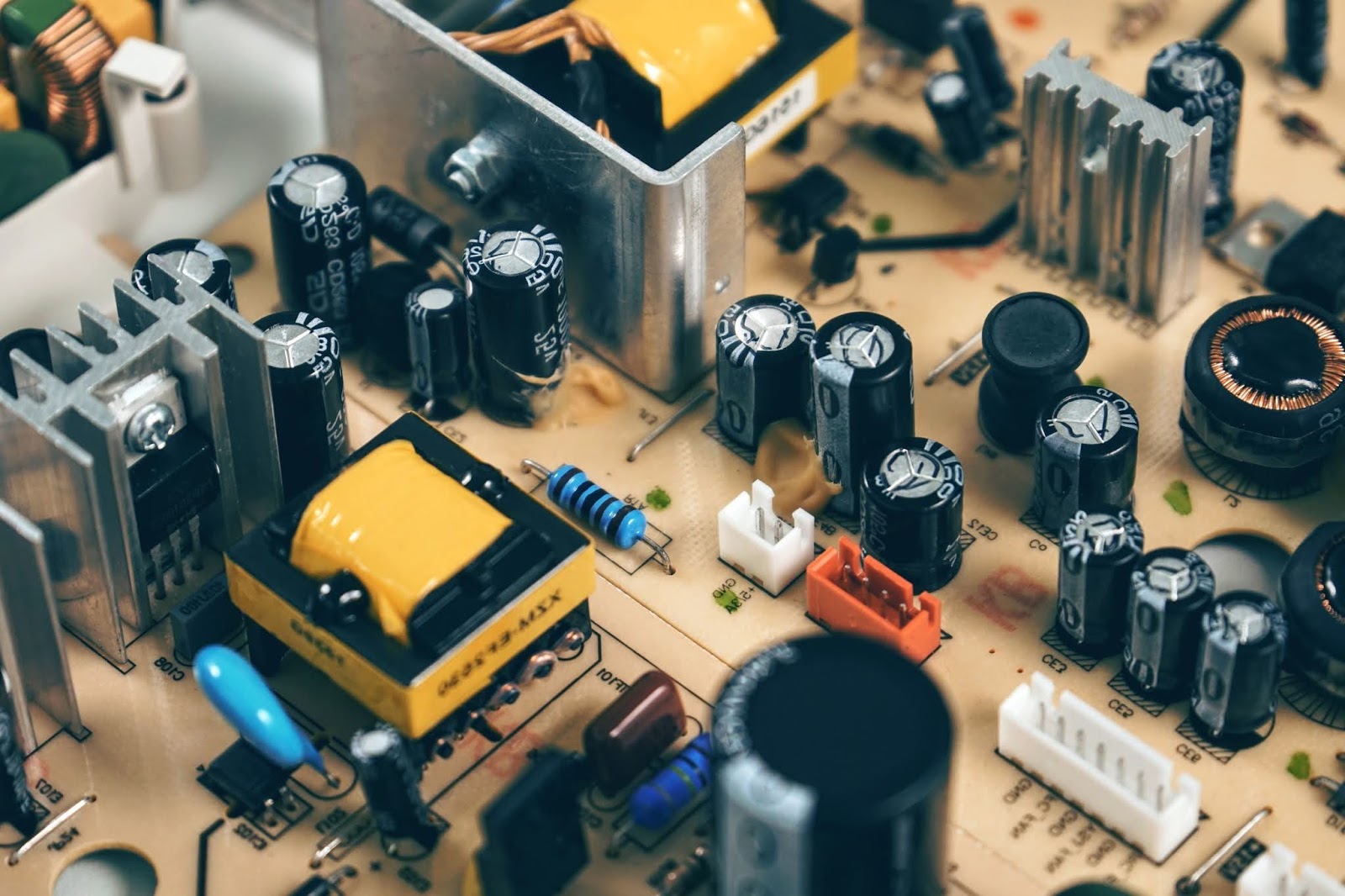

ELECTRONICS

AIR SEPARATION

FOOD AND BEVERAGES